Manufacturing with character

Manufacturing by hand. Producing higher quality.

Craftsmanship

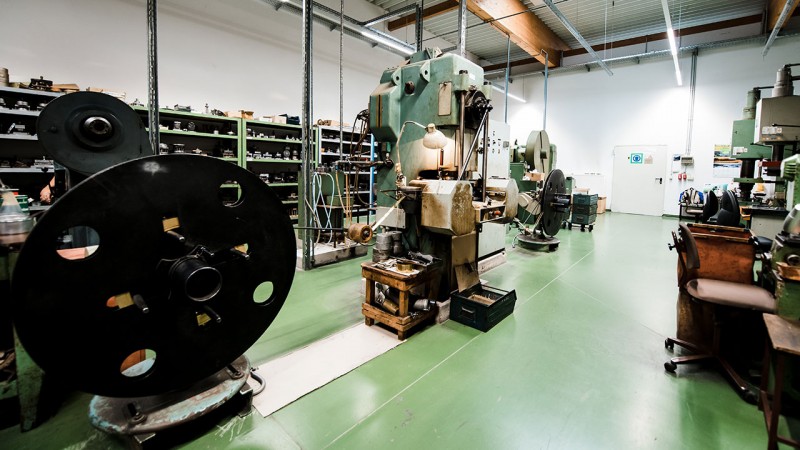

The precision mechanics company founded in 1945 by Kurt Fischeris a factory, which is regionally connected and produces exclusively in the Ore Mountains (Erzgebirge), Saxony. Thanks to its highquality measuring instruments for weather and climate, FISCHER enjoys an excellent reputation worldwide.

Passion & Precision

Through handmade production in our workshops as well as decades of professional competence, we create solid and durable instruments which are characterised by their precision. We strive for a healthy living and working climate, optimum sauna conditions, as well as accurate weather forecasts on water and on land.

Tradition & Experience

“The company has always been a big part of our family. We have all contributed to the success. My father, for example, is to be thanked for the precision of our hygrometers. In the 1960s, he intensively pushed forward research and development in this field. I myself as a student worked in different departments during the holidays. After my studies, I took over the sales management at FISCHER. To continue the family work in the third generation is a great challenge and, at the same time, a wonderful task.“

Peter Fischer

Handicraft production

for better quality, functionality and appearance

Expertise and precision work

“A lot of handiwork and a lot of love is placed in it.”

Mandy Gerlach

Mandy Gerlach (38) works in the paint shop at FISCHER and knows that accurate work is essential. “You have to set the spraying roundel for every set“. Of course, this takes a lot of effort, but it is also valued by the customers. Because they appreciate traditional handicraft. Mandy Gerlach consciously chose FISCHER. “It‘s not a newfangled business. It has existed for many years and has values and experience.“ Even her grandfather used to be employed in the company.

She likes working at FISCHER because she likes the family atmosphere. As a native of Drebach, she has known many of the employees since childhood.

This trusting cooperation is good for motivation. “A good working environment begins when colleagues get along.“

“We are happy to implement customer-specific developments.”

Marko Richter

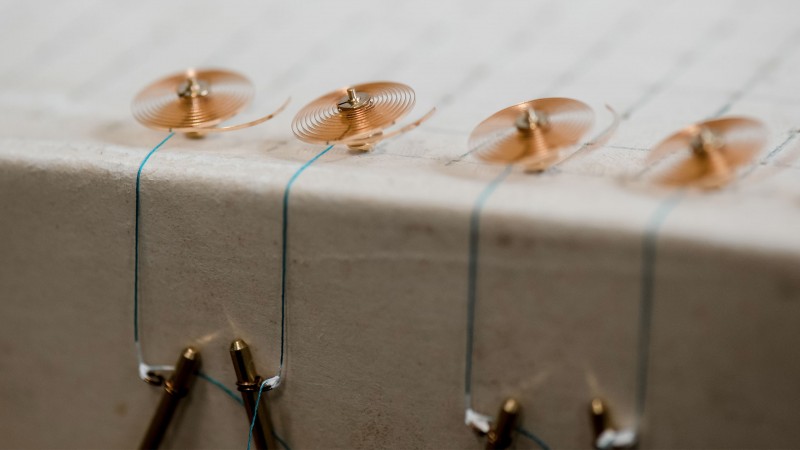

Marko Richter (41) is responsible at FISCHER for prototype construction and product optimisation, but also for the assembly of certain serial devices. He is also responsible for custom-made products. Technically sophisticated products with a brilliant design have always interested him. The personal favourites of the master craftsman are two devices in small series: “I like the barograph above all because of its technology, the weather column because of its exclusive appearance“.

For Marko Richter, the job at FISCHER is a stroke of luck. The company is regionally linked, internationally renowned and he can identify himself with the precision mechanical products.

Mandy Rudolph

Mandy Rudolph (45) is responsible for the printing of the scales at FISCHER. “My work is very varied because I use different printing methods: Screen, pad and digital printing.“ Each of the three techniques has its own particularities that need to be taken into account. For example, ambient temperature plays an important role. Mixing the colours also requires a lot of experience and tact. She is only satisfied when the result is perfect. “After all, FISCHER instruments are not only purchased for their quality and functionality, but also for their appearance.“

Mandy Rudolph feels comfortable at FISCHER. On the one hand, because she appreciates the good cooperation. On the other hand, because of the company‘s long tradition.

“You get better results by handcrafting.”

Jörg Norberger

Jörg Norberger (54) joined FISCHER immediately after his apprenticeship as a precision mechanic and has been employed here for 37 years. His tasks include the assembly of precision barometers - consisting of 80 individual parts. Very delicate and demanding work: “The instruments have to be adjusted to exactly 0.4 hPa“. If this tolerance is exceeded, readjustment and offsetting have to be done again. The instruments must have the same deviation at -35° and +40° as at room temperature. A few years ago, he travelled to the USA for FISCHER to test and adjust precision barometers ordered by the US Navy. “They had to meet the requirements to 100%.“ For this purpose, he and his colleagues had even set up a pressure chamber in the hotel room. Not an easy undertaking, but they also mastered this challenge.

“All parts must work perfectly.”

“A lot of handiwork and a lot of love is placed in it.”

“We are happy to implement customer-specific developments.”

“All parts must work perfectly.”

Learn more about FISCHER

Browse through our shop, experience the exclusive FISCHER Edition or discover the diverse application possibilities of our products.

“You get better results by handcrafting.”